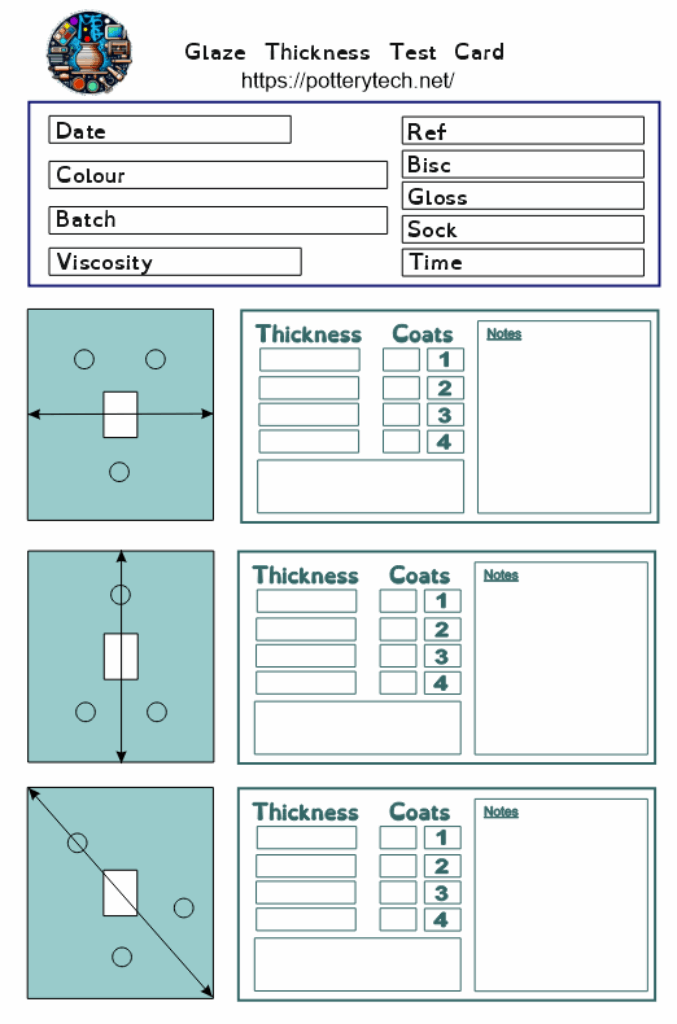

Glaze Thickness Measuring Tool

Introducing the PotteryTech Glaze Lab, the digital brain for your Penetrometer tool. This application replaces the messy paper notebook with a smart, interactive dashboard.

How it helps your studio:

Replicate: Use the “Compare” feature to match today’s batch against a successful firing from six months ago.

Measure: Take 3 readings per coat to account for hand variance.

Analyze: The app automatically calculates the average and plots it on a variance graph.

Standardize: Set a “Target Thickness” line on the graph and keep applying layers until you hit the green line.

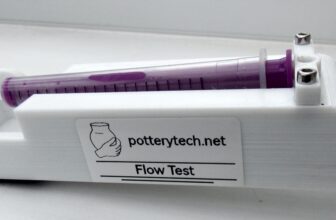

One of the projects I am working on involves creating a glaze medium in which a dry powder is mixed with the solution at a specific ratio. The next step required me to ensure that the glaze remained in suspension; I did not want it to settle over time, and most importantly, I wanted to avoid using traditional gums. Therefore, I adopted a completely different method for producing the glaze mediums. The project is now nearing completion after numerous trials and extensive experimentation. I have successfully developed a glaze medium that prevents any incorporated glaze from degrading or settling at the bottom of its container, which can occur with the conventional mixing method that employs water, gums, and other additives that may separate over time, leading to waste if the mixture cannot be remixed.

After finalizing the glaze medium, I moved on to the next phase, which involved designing a tool for measuring viscosity. To accomplish this, I created a 3D-printed viscometer, allowing me to assess the various powder-to-medium ratios and document the viscosity while determining the best brushing technique.

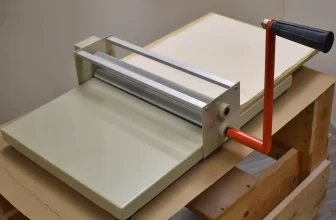

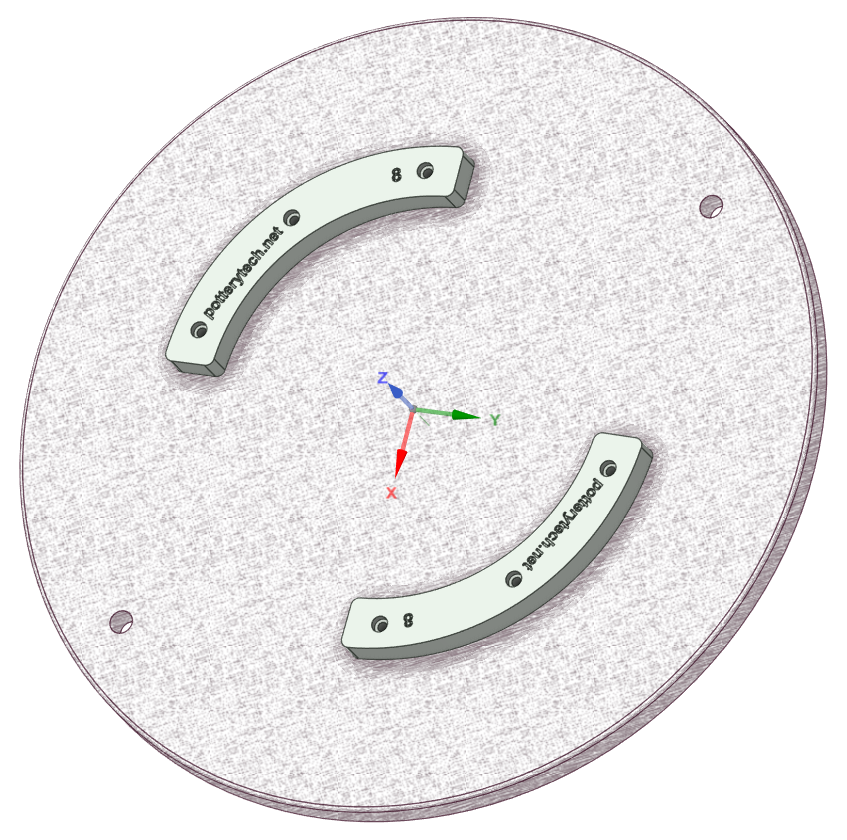

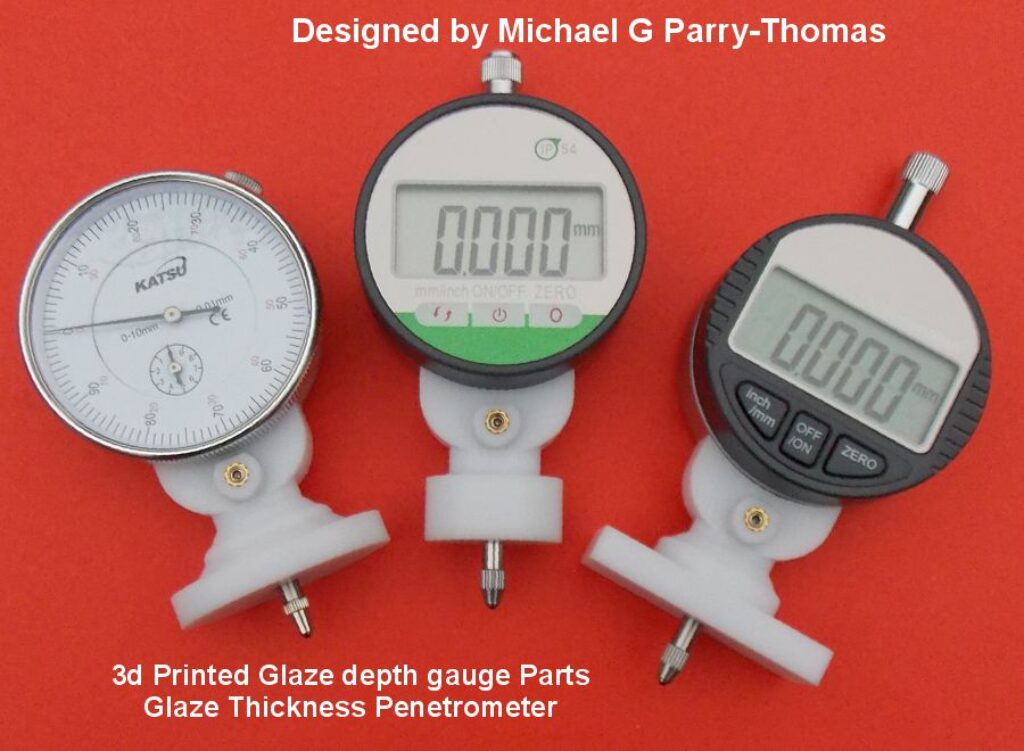

The subsequent stage of the project is to evaluate the thickness of the dry glaze. This necessitated the creation of a new instrument designed to measure the glaze’s adherence on the biscuit. I 3D-printed several different styles of adapters and arrived at an optimal solution that was both repeatable and, most importantly, durable for the leveling of the Penetrometer surface.

During the development of the glaze thickness measuring tool, I chose to design a version that would accommodate various leveling points. These points can be swapped out, featuring sharp edges that can slice through the glaze, as well as flatter ones that rest on the surface. The advantages of 3D printing enable the refinement of this system over time, allowing for continuous improvement.

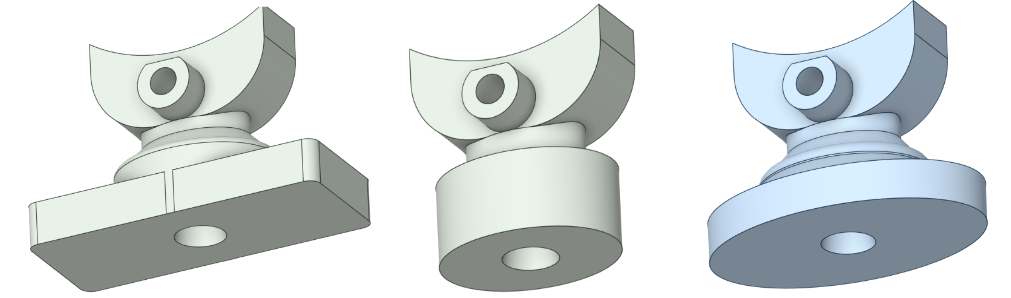

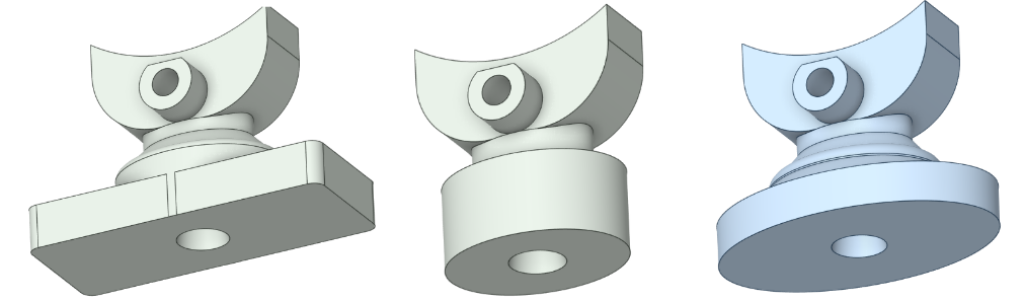

I was uncertain whether this was feasible, but I opted to 3D print the part using PETG filament with a fill density of 95%, a hot end temperature of 220°C, and a bed temperature of 70°C. The challenge with printing a flat surface you must account for material distortions and how the edges might begin to warp. Hence, I decided to design a set of 3 distinct leveling heads.

Using my preferred CAD software, DesignSpark Mechanical , I explored different concepts and ultimately arrived at a viable solution—please refer to the accompanying images.

After printing each piece, I made sure to treat the bottom surface to achieve a level finish, which can be particularly difficult with 3D printed materials. The initial task was to embed brass inserts to secure the leveling block to the instrument.

Following that, I focused on fine-tuning the flat surface. I had to develop a repeatable process, and after numerous attempts, I succeeded in refining the base face. This involved using a dressing system that utilized oil and various polishing compounds. I was pleasantly surprised by how level each facet turned out to be.

Digital Micrometer 0.001mm Electronic Micrometer Metric IP54 Waterproof 0-12.7mm Precision Dial Indicator Gauge Meter Tools

Penetrometer Measuring glaze thickness

3D Printed ,Features a system with 3 pin locating points

This tool for measuring the thickness of glaze features a system with three pin locating points. I created this glaze thickness measurement device to be suitable for use on any ceramic piece. The tool can accommodate various types of locating leveling pins, including flat pins and pointed pins, available in different lengths to address diverse measuring scenarios. This is especially useful in situations where standard glaze measurements on a glazed tile are challenging to obtain. You can employ this tool right after you have applied your glaze by either dipping or brushing it on. The process involves scraping a small area down to the biscuit layer and then zeroing the instrument on a leveling calibration block. Next, you position the depth gauge onto the glaze pot, ensuring that the center point makes contact with the biscuit. This method provides a precise measurement of glaze depth down to 0.001 mm, which is equivalent to 1 µm. Utilizing a three-pin locating leveling technique enables the tool to achieve self-leveling on uneven surfaces, ensuring that you receive an accurate reading of the glaze thickness.