Upgrading My Banding Wheel-Whirler with Custom 3D Printed Brackets

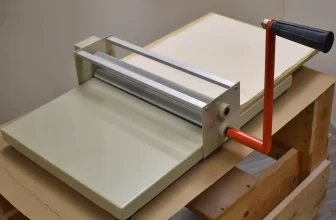

Recently, I realized I needed a bigger banding wheel-whirler, as my current one has a diameter of only 8 inches. Banding wheels are essential tools for any hobbyist’s workshop. They come in different sizes and materials such as cast iron, aluminum, and plastic, with prices varying accordingly. My banding wheel is made of aluminum, and I recommend choosing a metal option because these tend to be more durable, last longer, and can support heavier pots—offering reliable use for years.

A banding wheel-whirler has a bearing that allows the top plate to rotate smoothly. It mainly consists of two discs connected by a shaft and bearing. When I design patterns or use decorative techniques on my pots, I rely on my banding wheel-whirler for precise control. While I sometimes use my throwing wheel, I prefer the banding wheel because it sits at a comfortable tabletop height.

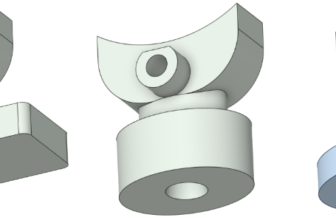

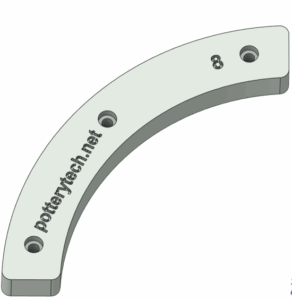

Sometimes, however, the pot or wooden bat shifts slightly on the banding wheel, especially when exact centering is crucial. To solve this problem, I designed and 3D printed locking locating brackets.

Using my favorite CAD software, DesignSpark Mechanical, I designed the brackets and printed them with PETG filament. I chose a wooden bat larger than my banding wheel and carefully aligned it, using circular guides to position the wheel correctly. Then, I flipped the banding wheel upside down and attached my 3D printed brackets to the bottom, securing the bat firmly in place.

These brackets prevent slipping during use and allow for easy removal from the banding wheel. This project is a great example of how 3D printing can help create custom tools that improve workflow and precision.

There are many types of banding wheel-whirlers on the market, but I recommend choosing cast iron or aluminum models because of their strength and longevity. Currently, I use an Aluminum Hobby Whirler, three wooden bats of different sizes, and my custom 3D printed locating brackets to make my pottery work smoother and more accurate.

3D printed locating locking bracket for a Banding wheel-whirler

designed by Michael G Parry-Thomas