When we prepare a batch of our brushing glaze medium, we conduct several tests to ensure that our clear brushing glaze adheres to the biscuit with the appropriate consistency. Our biscuit is fired at a temperature of 1000°. After this, we proceed to apply any under-glaze or other decorative effects onto the biscuit, followed by the application of two coats of our clear brushing glaze. To control the thickness of our lead-free glaze, we begin by measuring the temperature of the sample, then we utilize a viscometer to assess its consistency. Based on this assessment, we adjust the brushing glaze to ensure it aligns with our established standard.

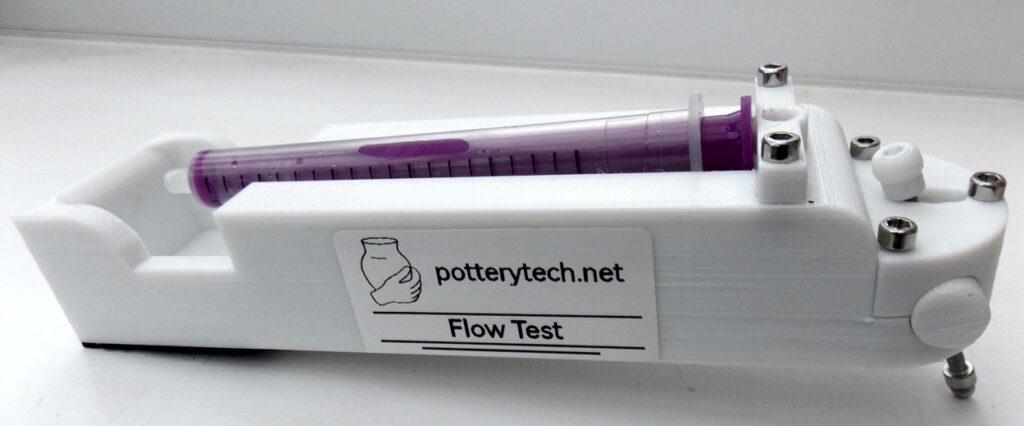

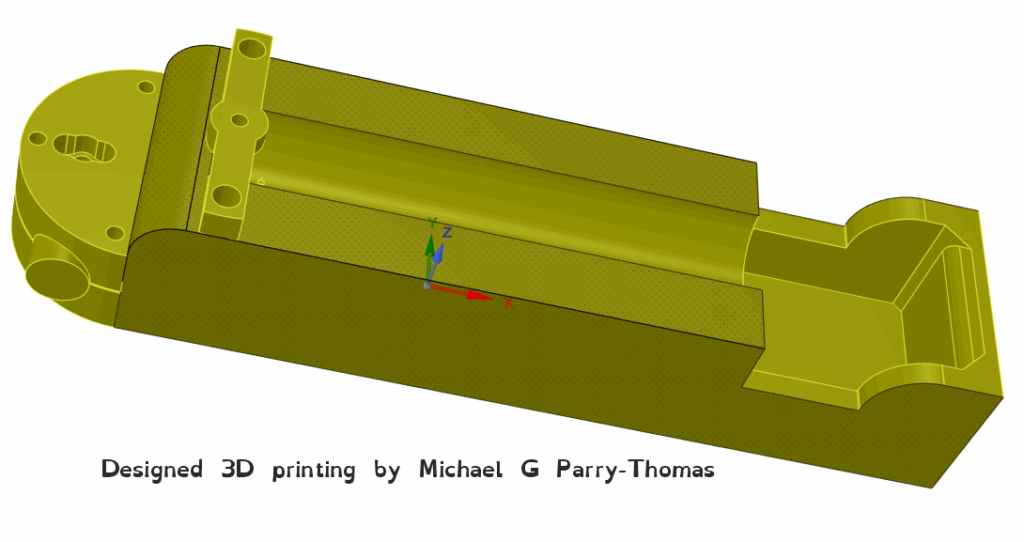

Next, we evaluate the flow of the brushing glaze medium that we obtain after applying it with a brush, before the surface dries. The flow test utilizes a specially designed instrument that has been 3D printed in-house. Initially, we set the device to a 20° incline by adjusting a setscrew located at the back of the instrument. Following this, we stir our brushing glaze , then fill a syringe with the glaze and position it into the instrument’s loading support. By pressing down on the plunger, the glaze starts to flow down the incline. Once the syringe is empty, we time the flow for 60 seconds using a stopwatch, measuring how far the glaze has flowed at that point, which provides us with a measurement in millimeters.

We also conduct this test at a temperature of 20°C as an additional measure for our brushing medium. This flow evaluation helps minimize any brush marks, as the glaze is suspended in a medium that incorporates some fluidity, helping to smooth out any imperfections that may occur during the brushing process. While it is not critical, since the surface of the glaze naturally flows and evens out during firing, we aim for a bit more ease-of-use when applying our clear brushing glaze.