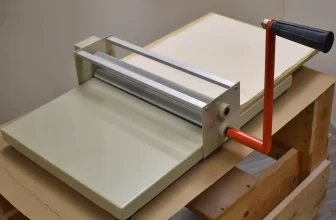

Recently, I upgraded my 3D printer to a direct drive system, which allowed me to utilize a much broader selection of 3D filaments. One of the most challenging materials I’ve encountered is TPU, which is a very stretchy filament and can be tricky to print. To test this filament, I opted to print some flexible rib tools that I could use during my hand-building and throwing processes. I wanted the material to have flexibility, so I used the 95A TPU filament. I was quite impressed with how they turned out; they printed perfectly with the modifications I made. This upgrade provides me with greater versatility in crafting my own pottery tools with flexible materials.

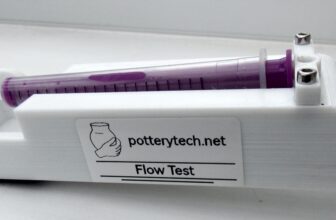

One of the crucial settings on the 3D printer was increasing the flow rate to 1.5. This adjustment was necessary because the material has a soft, rubbery texture, so by boosting the flow rate, I was able to squeeze more filament, effectively compacting it together. This indeed enhances the overall quality when working with TPU. Additionally, it’s essential to ensure that the temperature is adjusted to the optimal level for the specific filament being used, as different manufacturers often employ varying formulations. Therefore, conducting a temperature tower test and a flow rate test is vital.

These red flexible rib tools are excellent for various modelling techniques, throwing, and smoothing out clay during different clay manufacturing processes. At times, having a tool customized for a particular application becomes necessary, and this is where TPU shines, as it can be made incredibly flexible. However, the stiffness of the material can also be modified by altering the infill; increasing the infill results in a stiffer material.

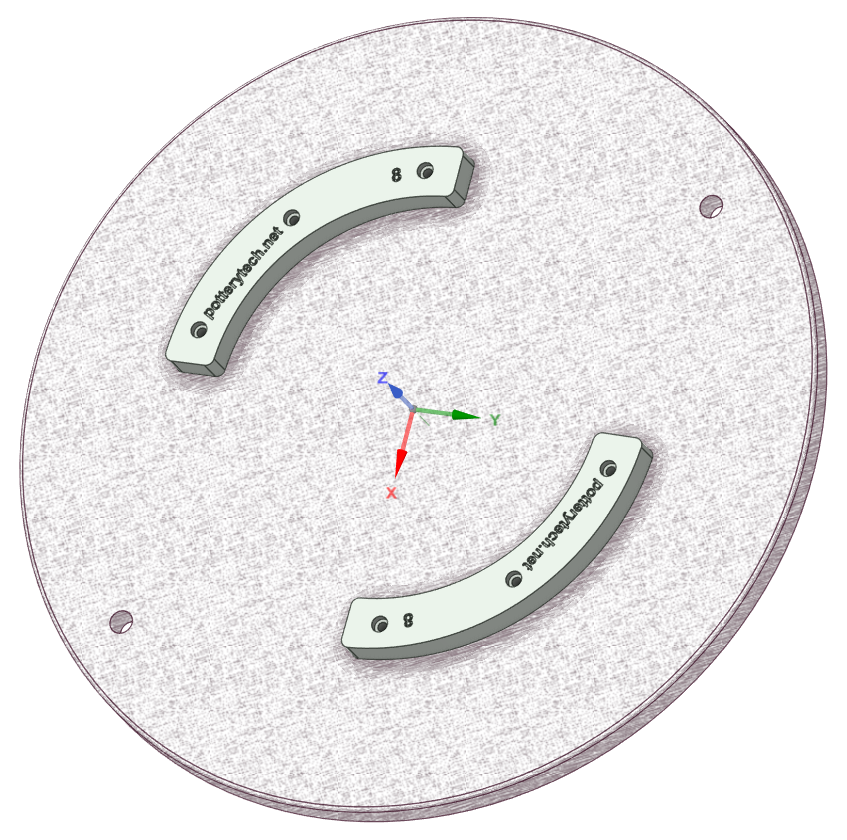

The two rib tools were open sourced from Thingiverse